« Nous avons acquis en 2015, un Optimiseur Linéaire au Rabotage de VAB Solutions. Nous avions déjà dans nos autres usines des systèmes de marques concurrentes. Nous avons décidé d’arrêter notre choix sur l’optimiseur de VAB pour notre site de Chertsey pour plusieurs raisons :

1- Après une analyse de calcul de retour sur investissement réalisé avec VAB Solutions

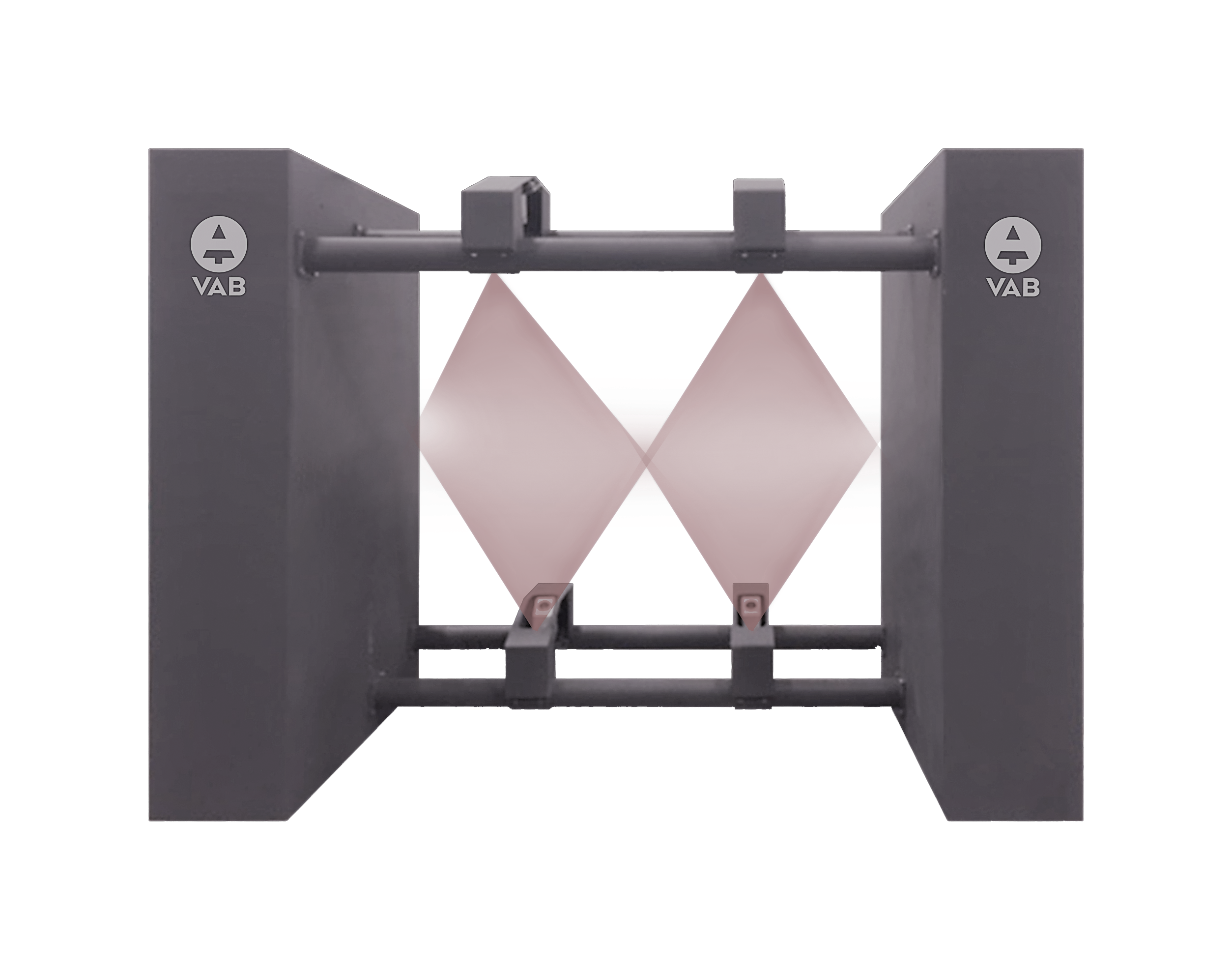

2- De par la simplicité du système, ces dimensions compactes et ses composantes minimales

3- Suites aux bonnes références que nous avons reçues de leurs clients tant pour la qualité du système que de leur services

Bref, après analyse c’est le système qui nous offrait le meilleur prix/retour sur investissement. Un an après l’installation de notre optimiseur de VAB, nous avons acquis le module tracheid et par la suite, le module du Air Board Tracker. Ceci démontre bien notre niveau de satisfaction. »

M. Dominic Venne, Production & Quality Superintendent

Groupe Crête – Québec